Conco FinGuard ACC™ Sleeving Saves Plant Time and Money

Yellowstone Power Plant, Billings, Montana.

Yellowstone Power Plant in Billings, Montana, was particularly concerned when leak testing indicated more than a hundred tube leaks were adversely affecting their turbine's performance. "We have more than twelve thousand elliptical finned tubes in our air-cooled condenser," said Tom Shaw, Yellowstone's plant manager. "Made of cold-dipped galvanized carbon steel, each tube is thirty feet long with a two-inch-wide elliptically shaped diameter. In our case, we believe the holes, ranging from ½" to ¾" in diameter, resulted from the exterior water spray system we use to augment two twenty-six-foot-diameter cooling fans during the warm weather seasons. We tried epoxy and gasket material, but without success. Other techniques, such as brazing, had some measure of success in plugging the tubes, but the work was extremely laborious and time-consuming."

Mr. Shaw spoke with engineers at Conco Systems, Inc. of Verona, Pennsylvania, who use their FinTech ACC™ air-cooled condenser cleaning system to clean Yellowstone's unit on a regular basis. With plant assistance, Conco began development of a new technology that would eliminate plugging and prove highly successful in restoring finned ACC tubes to service.

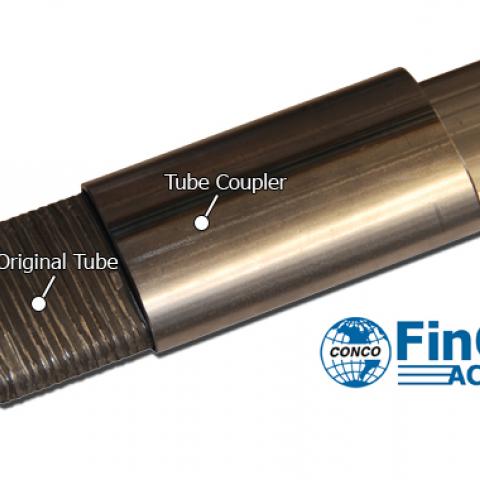

After a period of research and development involving various materials and manufacturing techniques, Conco has achieved a successful solution, termed the Conco FinGuard ACC™ Sleeve system, that employs elliptical shaped tube inserts and couplers that are used on site to bring a plant's ACC leaking or plugged finned tubes back into service. "A small section of the leaking finned tube is cut out using a hand-held grinder," said Mr. Shaw. "A new section of finned tube is placed between the cuts in the old tube and stabilized by inserting a 10" long elliptical sleeve. Both joints where the old and new finned tube sections meet are covered with a 4" long elliptical coupler. The sleeve adds internal support while the couplers provide external support. This permanent repair is bonded using a high-temperature RTV (room temperature vulcanizing) sealant."

Both the sleeve and coupler for FinGuard ACC™ are made from thin walled carbon steel tube material and are produced at Conco's manufacturing plant in Verona. The special elliptical shape is formed in a stamping die using a mechanical press. While in this case the elliptical geometry of the sleeve and coupler were designed specifically for the tube geometry at Yellowstone's plant, Conco can custom design tooling to produce sleeves and couplers for almost any tube geometry.

"Air in-leakage through condenser tube holes can dramatically affect a power plant's performance," said Mr. Shaw. "As the backpressure increased at Rosebud because of this in-leakage, we experienced reduced operating efficiency and increased generation costs. After re-sleeving the bad tubes, we saw our backpressure go from 7 ½ HgA down to 6 ¼ HgA. That's a tremendous improvement. It allows us to use less steam to power the turbine. With our air-cooled condenser, we can now operate at higher ambient temperatures and maintain higher loads for a longer period of time. This new sleeving technology is cost-effective and helps us maintain MW output at less cost."